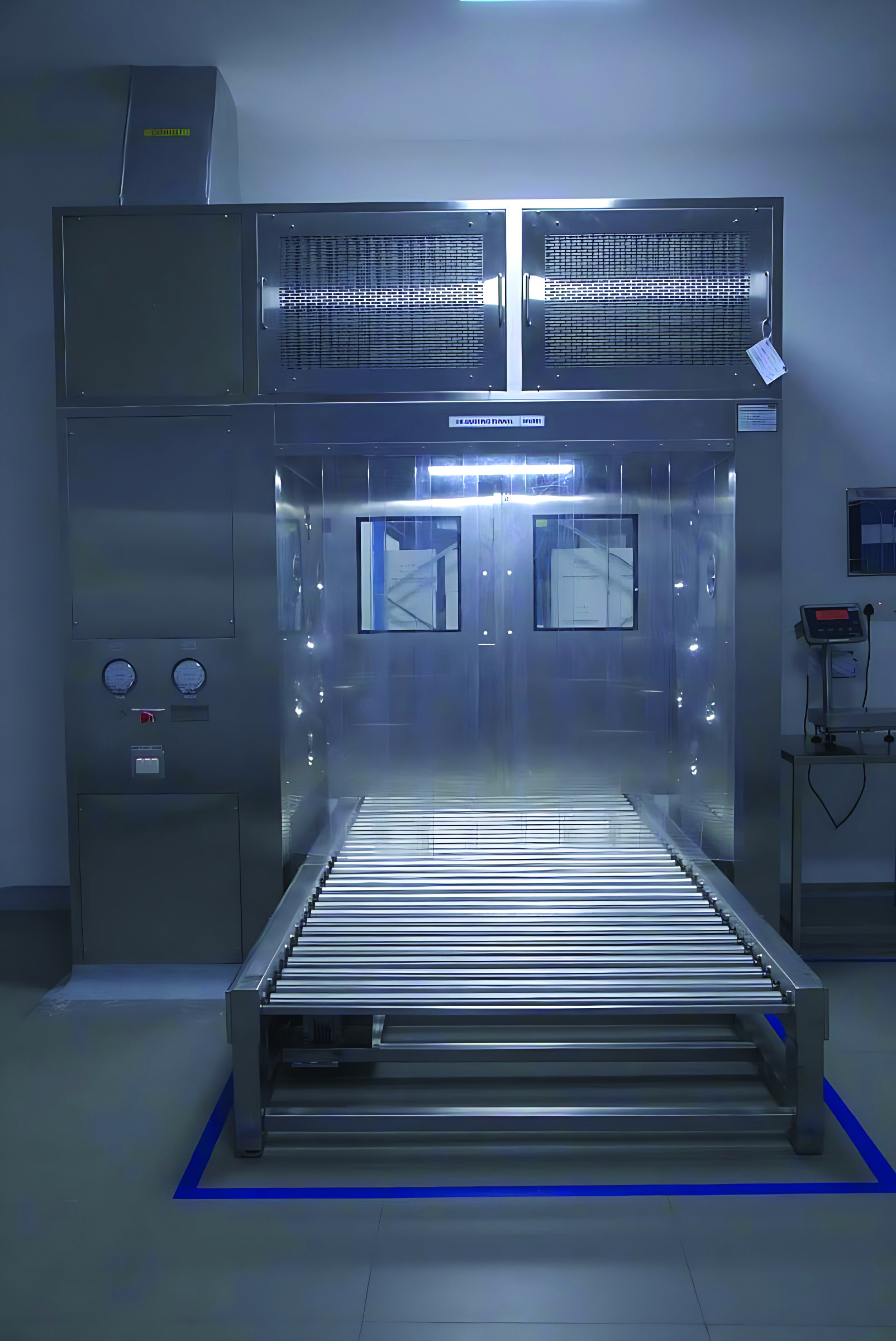

DEDUSTING TUNNEL

A dedusting tunnel of Syntec is therefore a must innovation in every cleanroom operation. The dedusting tunnels remove dust particles and other forms of contaminants from the materials quite effectively, ensuring product quality apart from operator safety. The tunnels of Syntec use high-velocity airflows, HEPA filtration, in addition to ionization (optional) to assure excellent particle removal efficiency. The tunnels are built in strong stainless steel with smooth non-porous surfaces so that there is particle collection and it also erects easy cleaning. Syntec tunnels have been designed in a variety of configurations, sizes, and based on your application. They can handle any size of the material that you may be dealing with as far as large heavy gauge structures. Basically, whether you need a small capacity tunnel or an extensive high-capacity tunnel system for a large production, Syntec has everything figured out for you. With Syntec dedusting tunnels, your sensitive products can be afforded protection from air pollutants, reducible chance of product contamination, your operators from harmful dust exposure, improved general cleanroom efficiency and safety, as well as strict standards and regulations that seeks to maintain a sterile clean room.

Contact Syntec today concerning your dedusting tunnel requirements to specifically meet the needs of your particular facility while improving cleanroom operations' efficiency and safety.